Outstanding quality management system

At Exlabesa, we employ a rigorous quality management system. This ensures that the aluminium we use has been sustainably sourced and is of the highest possible quality. It also continuously checks our operating procedures to ensure that our factories are working efficiently and are optimising procedures.

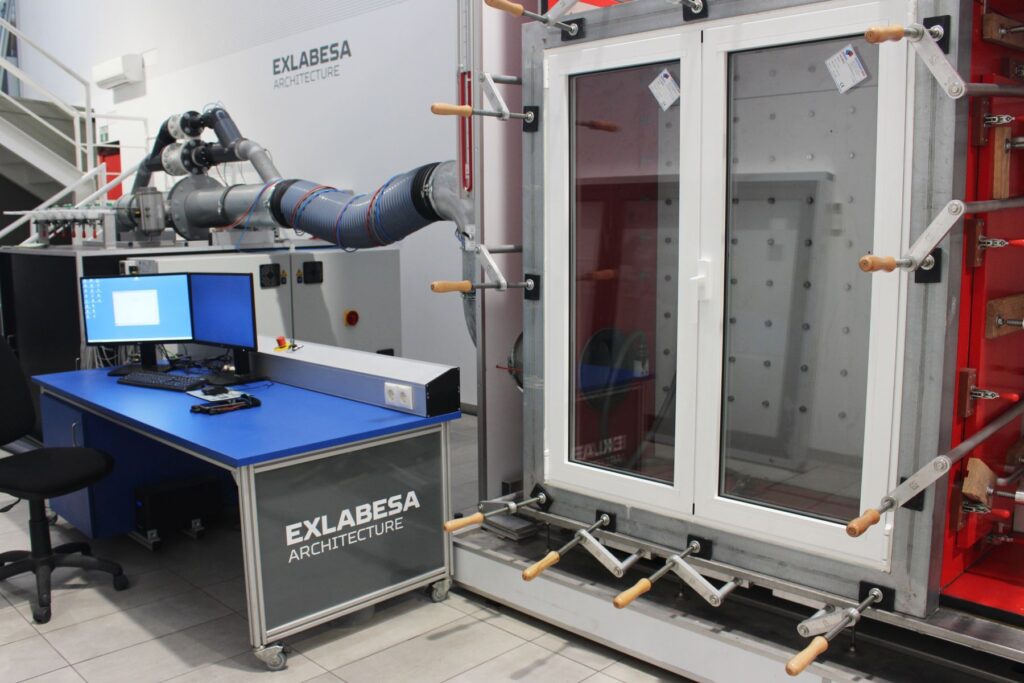

We employ a range of technology and industry specific expertise to test our products. We analyse the chemical composition of all our alloys to ensure consistence of quality. We use metallographic and resistance tests on our aluminium profiles during machining, anodizing, and powder coating to ensure that quality is maintained.

We are accredited by a range of third-party industry organisations and hold Qualicoat certification. Exlabesa is certified under the ISO 9001 Quality Management System and always prioritise both employee welfare and customer satisfaction.

100% recyclable aluminium systems

Aluminium is a 100% recyclable material. It can be melted down and reformed numerous times without losing any of its inherent qualities. At Exlabesa, we are committed to using 100% recycled aluminium wherever possible. We operate state-of-the-art recycling plants where our smelting furnaces are used to melt down used aluminium systems and components which are then used to extrude new aluminium profiles. This gives our aluminium systems a potentially infinite lifespan.

Recasting aluminium from used profiles and components uses only 5% of the energy involved in producing aluminium systems from raw material. This reduction makes a massive impact on the carbon emissions rate of the aluminium production process. At Exlabesa, we are dedicated to improving our aluminium processing and recycling operations to enable us to set the standards for global sustainability by minimising waste and promoting environmental protection.

Exlabesa Clean Planet

At Exlabesa Building Systems, we are dedicated to supporting environmental protection. To ensure that our processes are as eco-friendly as possible, we have developed Exlabesa Clean Planet. Exlabesa Clean Planet is an initiative based on the circular economy. It is designed to protect the environment by reducing the impact of our production processes on the environment. Our two aluminium recycling plants allow us to set the benchmark for environmental protection in the glazing industry and lead the field in terms of sustainability.

Clean Planet criteria

At Exlabesa, we are always looking for new ways to improve our production processes. Our commitment to environmental protection has enable us to reduce our carbon emissions over the last decade. Our aluminium systems can be recycled and re-used numerous times with no negative impact on the material’s quality. We truly believe that aluminium is the material of the future and will help to transform building projects across the world and help to create a more sustainable society for future generations.

Environmental protection

Protecting the environment is our main priority. All our production processes are designed to maximise environmental protection by reducing our carbon emissions and streamlining our manufacturing methods.

Sustainability

All our aluminium systems are sustainably produced. They have an infinite life cycle to minimise environmental impact using 100% recyclable aluminium.

Aluminium recycling

Aluminium is a 100% recyclable material. Exlabesa group has two aluminium recycling plants equipped with state-of-the-art melting furnaces, allowing us to reduce our carbon footprint by producing eco-friendly aluminium profiles. This mirrors our Clean Planet initiative and our drive towards environmental protection.

Material properties

Aluminium is a lightweight, strong, and durable material. It can be easily formed into a wide range of profile shapes and sizes for a selection of different applications. It is 100% recyclable and when reformed it loses none of its material characteristics.